Design and Prototypes

After years of working modelling and stressing other people’s designs I have started to design and manufacture my own equipment and components, obviously with a significant CAE and simulation aspect.

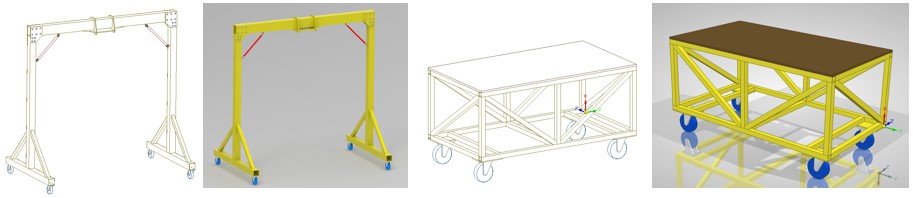

Gantry and Car Trolley

My workshop needed a crane/gantry to lift racing cars and their associated subsystems. If it was mobile, capable of lifting the Radical, and could be operated by one person, it would be a useful addition to my facilities. If I was going to do that a decent car trolley, or series of them would be useful too.

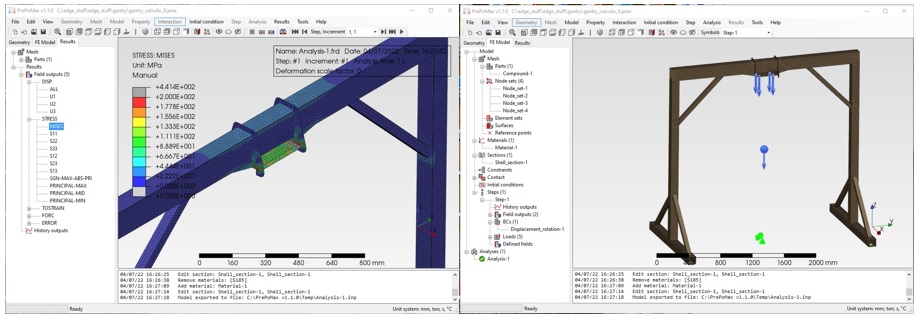

A full CAE representation of both systems was created and extensive FEA of the gantry were carried out. (The trolleys were only stressed using “traditional methods”).

This was also a good opportunity to benchmark PreProMax and Calculix against Abaqus.

The gantry was constructed in my unit in Bicester over the winter of 2021, laser cutting by Metweld of Banbury and welding by Jo White of Vulcandezign.

It has worked extremely well lifting the required weights with ease and allowing the lifting of a car to be a one man job. Pictures below taken during initial testing/commissioning. Note also one of numerous trolleys completed to date.

Tools and Components for Vintage Motorcycles

I’ve been helping a friend with parts and tools for his vintage motorcycle restoration projects. This has involved CAD design, rapid prototyping and more traditional manufacturing.

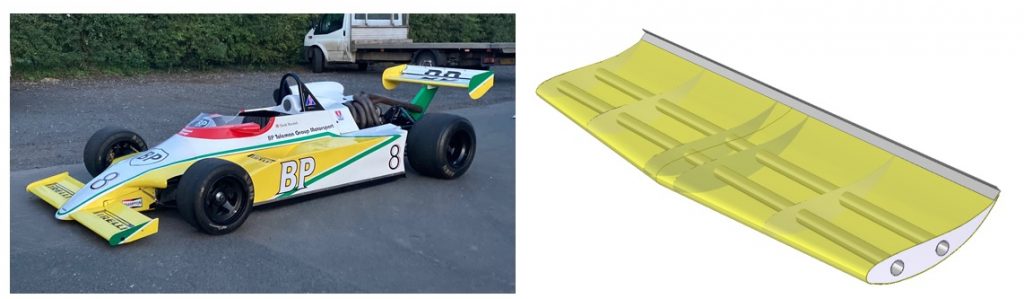

Assembly modelling for Toleman F2 rear wing

Jo White of VulcanDezign was commissioned to manufacture a new rear wing for a Toleman F2 car. This is the CAD assembly model I created to aid manufacture.

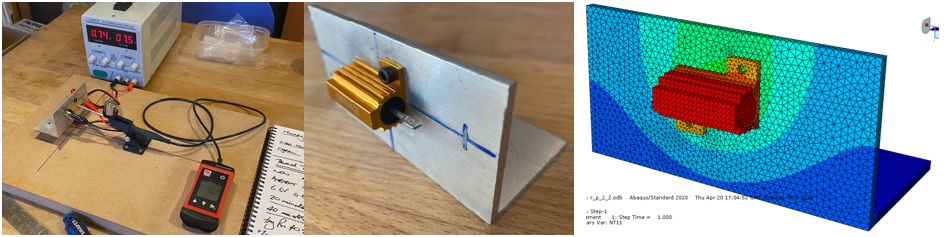

Electronics Testing

Recently I’ve been undertaking a series of experiments to validate and optimise thermal models of power resistors mounted on heatsinks.